Maintenance Overview: Protecting Your Investment

Professional Maintenance Benefits: Proper maintenance extends artificial hedge lifespan by 40-60%, maintains fire safety certifications, preserves aesthetic appeal, and reduces total cost of ownership for commercial properties.

Unlike natural landscaping that requires constant care, artificial hedges and living walls need minimal but strategic maintenance to preserve their appearance and performance. Commercial and hospitality properties that implement proper maintenance protocols see significant returns through extended product life, maintained safety compliance, and consistent brand image.

This comprehensive guide provides professional-grade maintenance strategies developed specifically for commercial environments where appearance, safety, and cost control are critical factors.

Key Maintenance Benefits for Commercial Properties

- Extended Lifespan: Proper care can extend artificial hedge life from 8-12 years to 12-18 years

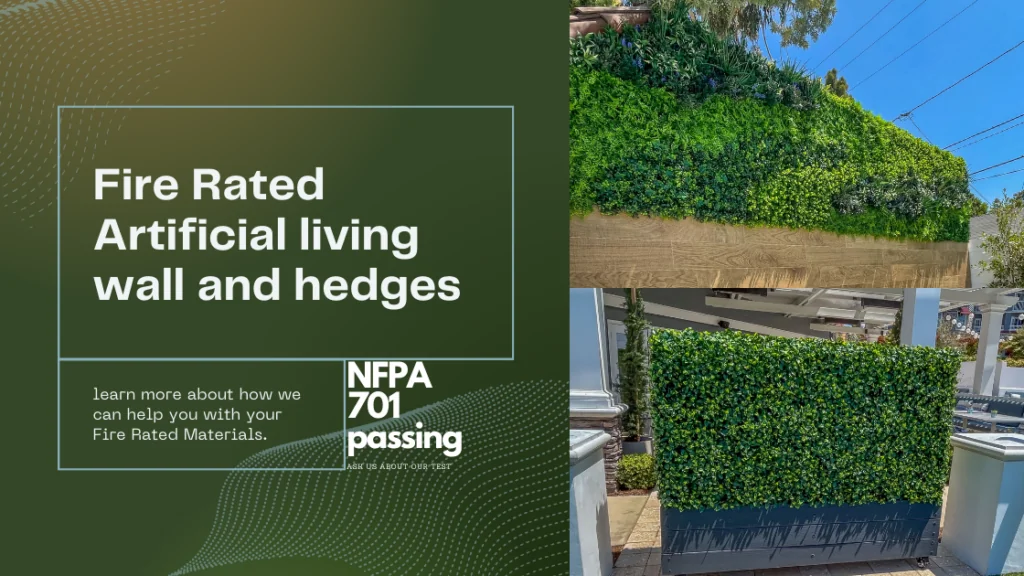

- Preserved Fire Safety: Maintains NFPA 701 Method 2 certification through proper cleaning

- Consistent Appearance: Ensures year-round professional brand image

- Cost Avoidance: Prevents premature replacement and emergency repairs

- Warranty Protection: Maintains manufacturer warranty coverage

- Insurance Compliance: Keeps coverage valid through proper care documentation

Professional Maintenance Schedule

Implementing a systematic maintenance schedule ensures optimal performance while minimizing labor costs and business disruption.

📅 Monthly Inspection

Every 30 Days

- Visual inspection for damage or wear

- Check mounting hardware security

- Document any issues or concerns

- Verify fire safety compliance

- Remove large debris accumulation

Time Required: 15-20 minutes per 100 linear feet

🧹 Quarterly Cleaning

Every 90 Days

- Surface dust and debris removal

- Spot cleaning for stains or marks

- Gentle washing with approved solutions

- Thorough rinse and air dry

- Touch-up minor repairs

Time Required: 45-60 minutes per 100 linear feet

🔍 Semi-Annual Deep Clean

Every 6 Months

- Comprehensive deep cleaning process

- Professional-grade equipment cleaning

- Complete mounting system inspection

- Fire safety recertification check

- Performance documentation update

Time Required: 2-3 hours per 100 linear feet

🛠️ Annual Professional Service

Every 12 Months

- Professional comprehensive inspection

- Specialized cleaning and restoration

- Hardware replacement if needed

- Warranty compliance verification

- Long-term planning assessment

Time Required: 4-6 hours per 100 linear feet

Step-by-Step Cleaning Process

Pre-Cleaning Assessment and Preparation

Safety and Documentation: Begin with a thorough visual inspection to identify any damage, loose components, or areas requiring special attention. Document the current condition with photos for maintenance records.

- Check for loose or damaged panels

- Identify stained or heavily soiled areas

- Verify mounting hardware integrity

- Note any fire safety concerns

- Plan cleaning approach based on conditions

Initial Debris and Dust Removal

Gentle Surface Cleaning: Remove loose debris, dust, and surface contaminants using soft-bristle brushes and low-pressure air flow. This prevents embedding particles during wet cleaning.

- Use leaf blower on low setting for large areas

- Employ soft-bristle brush for detailed cleaning

- Remove spider webs and insect debris

- Clear drainage areas and mounting points

- Vacuum loose debris from ground area

Washing and Deep Cleaning

Professional Cleaning Solution: Apply approved cleaning solutions using gentle techniques that preserve fire-resistant treatments and UV protection while removing stubborn dirt and stains.

- Mix mild soap solution (1:20 ratio with water)

- Apply with soft cloth or low-pressure spray

- Work from top to bottom in manageable sections

- Use circular motions for stubborn stains

- Avoid harsh chemicals or abrasive tools

Thorough Rinsing and Drying

Complete Residue Removal: Rinse thoroughly to remove all cleaning solution residue, which can attract dirt or affect fire-resistant properties if left on the surface.

- Rinse with clean water from top to bottom

- Use low-pressure setting to avoid damage

- Ensure complete soap removal from all surfaces

- Allow natural air drying (avoid heat sources)

- Check for water pooling in mounting areas

Final Inspection and Touch-Up

Quality Control and Documentation: Conduct final inspection to ensure cleaning quality and identify any maintenance needs for future attention.

- Verify uniform clean appearance

- Check for missed spots or residue

- Tighten any loose hardware discovered

- Document maintenance completion

- Schedule any needed repairs or touch-ups

Essential Tools and Supplies

🧽 Cleaning Supplies

- Mild Soap: pH-neutral cleaner (dish soap works well)

- Microfiber Cloths: Non-abrasive cleaning cloths

- Soft-Bristle Brushes: Various sizes for detailed work

- Spray Bottles: For controlled solution application

- Clean Water: Preferably filtered to avoid mineral deposits

🔧 Equipment

- Garden Hose: With adjustable pressure nozzle

- Leaf Blower: Electric preferred for noise control

- Ladder: Appropriate height with safety features

- Pressure Washer: Low-pressure setting only (under 1500 PSI)

- Extension Tools: For reaching high areas safely

📋 Maintenance Documentation

- Maintenance Log: Track cleaning dates and conditions

- Photo Documentation: Before/after condition records

- Issue Tracking: Record problems and solutions

- Warranty Records: Keep compliance documentation

- Service Contacts: Professional service provider list

⚠️ Safety Equipment

- Safety Glasses: Eye protection during cleaning

- Work Gloves: Non-slip grip gloves

- Non-Slip Shoes: Appropriate footwear for wet conditions

- First Aid Kit: Basic medical supplies on site

- Communication Device: Cell phone or radio for emergencies

Seasonal Maintenance Considerations

🌱

Spring Preparation

- Post-winter damage assessment

- Remove accumulated debris

- Check mounting after freeze/thaw cycles

- Plan maintenance schedule for year

- Inspect for pest nesting

☀️

Summer Intensity

- UV exposure monitoring

- Increased cleaning frequency in dusty areas

- Heat stress inspection

- Irrigation system interference check

- Early morning cleaning preferred

🍂

Fall Preparation

- Heavy leaf debris removal

- Pre-winter comprehensive cleaning

- Hardware winterization check

- Drainage system clearing

- Storm preparation assessment

❄️

Winter Protection

- Snow and ice removal

- Freeze damage prevention

- Reduced cleaning frequency

- Indoor facility focus

- Spring planning preparation

Common Installation Issues and Solutions

Problem: Fading or Color Changes

Solution:

Fading typically indicates UV protection breakdown. Clean thoroughly with approved solutions, check warranty coverage, and consider professional restoration services. For severe fading, panel replacement may be necessary. Document with photos for warranty claims.

Problem: Dust and Dirt Accumulation

Solution:

Increase cleaning frequency during dusty seasons. Use leaf blowers for regular surface cleaning between deep cleans. Consider installation of windscreens in particularly dusty environments. Ensure proper drainage to prevent mud splashing.

Problem: Loose or Damaged Panels

Solution:

Immediately secure loose panels to prevent further damage. Check mounting hardware for corrosion or wear. Replace damaged fasteners with stainless steel alternatives. Document damage for warranty consideration and insurance claims if applicable.

Problem: Staining from Building Runoff

Solution:

Address staining immediately while fresh. Use specialized cleaning solutions for metal or mineral stains. Install gutters or drainage modifications to redirect runoff. Consider protective treatments for areas prone to staining.

Problem: Pest Nesting or Infestation

Solution:

Remove nests carefully during non-breeding seasons. Seal gaps where pests might enter. Use humane deterrents rather than chemicals. Consider professional pest control consultation for persistent problems. Regular inspection prevents major infestations.

Problem: Weather Damage (Wind, Hail, Ice)

Solution:

Document damage immediately with photos for insurance claims. Secure any loose materials to prevent further damage. Contact professional services for assessment of structural integrity. Keep detailed maintenance records to support insurance claims.

Cost-Saving Maintenance Strategies

40-60%

Lifespan Extension

Proper maintenance can extend artificial hedge life from 8-12 years to 12-18 years, significantly reducing replacement costs and improving ROI.

$200-500

Annual Maintenance Cost

Professional maintenance costs $2-5 per linear foot annually, far less than the $15-35 per linear foot for natural hedge maintenance.

$5,000-15,000

Avoided Replacement Costs

Proper care prevents premature replacement, avoiding costs of $50-120 per linear foot for new installation.

100%

Warranty Protection

Following maintenance guidelines preserves manufacturer warranty coverage, protecting against defective materials and workmanship.

Professional vs. In-House Maintenance

| Service Type | In-House Cost | Professional Cost | Recommended Approach |

|---|---|---|---|

| Monthly Inspection | $25-50 per visit | $75-125 per visit | In-house with proper training |

| Quarterly Cleaning | $100-200 per cleaning | $200-350 per cleaning | In-house for cost savings |

| Semi-Annual Deep Clean | $300-500 per service | $500-800 per service | Professional for best results |

| Annual Professional Service | Not recommended | $800-1,200 per service | Always use professionals |

| Repair and Restoration | Limited capability | $150-300 per hour | Professional for warranty compliance |

Conclusion

Effective maintenance of artificial hedges and living walls is a strategic investment that protects your commercial property investment while ensuring consistent performance and appearance. With minimal effort compared to natural landscaping, proper maintenance protocols can extend product life significantly while maintaining fire safety compliance and aesthetic standards.

The key to successful maintenance lies in consistency, documentation, and using appropriate techniques that preserve the integrity of fire-resistant treatments and UV protection. Commercial properties that implement these professional maintenance strategies consistently outperform those with ad-hoc approaches in terms of appearance, longevity, and total cost of ownership.

Maintenance Success Formula: Regular inspections + proper cleaning techniques + professional annual service = maximum lifespan, preserved warranties, and optimal return on investment for commercial artificial landscape installations.

By following this comprehensive maintenance guide, commercial and hospitality properties can ensure their artificial hedges and living walls continue to provide the aesthetic appeal, environmental benefits, and operational advantages that justified the initial investment.