Installation Overview and Project Planning

Professional Installation Success: Proper installation is critical for longevity, safety, and aesthetic appeal. This guide provides industry-standard techniques used by professional installers for commercial and hospitality projects.

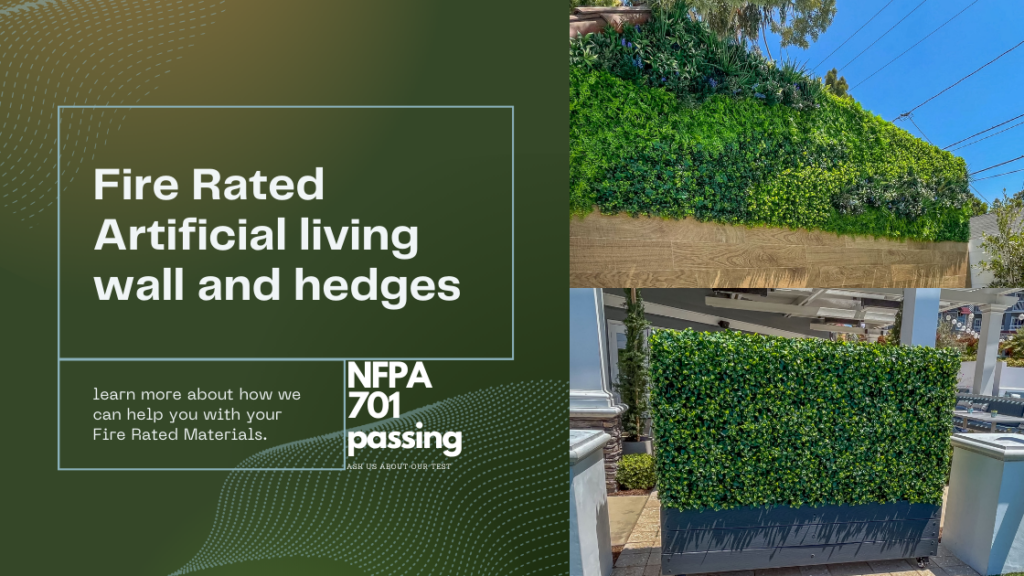

Installing artificial hedges and living walls requires careful planning, the right tools, and attention to detail. Unlike simple residential installations, commercial and hospitality projects demand higher standards for safety, durability, and aesthetic consistency.

Professional installation ensures your artificial landscape materials maintain their appearance, meet safety requirements, and provide years of maintenance-free service. This comprehensive guide covers everything from initial planning to final quality control.

Pre-Installation Planning Checklist

- Site Assessment: Evaluate installation surface, environmental conditions, and accessibility

- Measurement Verification: Confirm all dimensions and create detailed installation drawings

- Material Inspection: Verify product specifications, quantities, and quality standards

- Code Compliance: Ensure all materials meet local building codes and fire safety requirements

- Safety Planning: Develop safety protocols for installation team and site conditions

- Schedule Coordination: Plan installation timeline to minimize disruption to business operations

Installation Timeline for Different Project Types

| Project Type | Typical Duration | Team Size | Key Considerations |

|---|---|---|---|

| Small Hedge Installation (under 50 linear feet) | 4-6 hours | 2 installers | Single-day completion, minimal disruption |

| Medium Living Wall (200-500 sq ft) | 1-2 days | 2-3 installers | Structural mounting, electrical coordination |

| Large Commercial Installation (500+ sq ft) | 3-5 days | 3-4 installers | Phased installation, quality control checkpoints |

| Hospitality Complex Project | 1-2 weeks | 4-6 installers | Multiple locations, guest area coordination |

Essential Tools and Equipment

Professional Tool Investment: Using proper tools is essential for efficient installation and professional results. Quality tools reduce installation time and ensure consistent outcomes across projects.

🔧 Power Tools

- 18V cordless drill/driver

- Impact driver for heavy-duty fasteners

- Circular saw or miter saw

- Oscillating multi-tool

- Angle grinder (for metal cutting)

📏 Measuring & Layout

- 25-foot measuring tape

- 4-foot level

- Laser level (for large installations)

- Chalk line

- Speed square

🔩 Fasteners & Hardware

- Stainless steel screws (various lengths)

- Concrete anchors and wall plugs

- Galvanized brackets and clips

- Weather-resistant washers

- Cable ties and zip ties

🦺 Safety Equipment

- Safety glasses and hearing protection

- Work gloves (cut-resistant)

- Hard hats for commercial sites

- Safety harnesses for height work

- First aid kit

🪜 Access Equipment

- Extension ladders

- Scaffolding for large walls

- Step ladders (various heights)

- Ladder stabilizers

- Non-slip ladder feet

🧰 Specialty Tools

- Masonry bits for concrete

- Hole saw set

- Stud finder

- Utility knife

- Wire brush for surface prep

Step-by-Step Installation Process

Site Preparation and Surface Assessment

Surface Evaluation: Inspect the mounting surface for structural integrity, levelness, and any obstacles. Document any issues that need addressing before installation.

- Check wall condition and identify any repairs needed

- Locate utilities and mark any areas to avoid

- Clean the surface of dirt, debris, and loose material

- Verify surface material (wood, concrete, metal, etc.)

- Test for moisture issues or drainage problems

Layout and Measurement

Precision Planning: Create a detailed layout ensuring perfect alignment and professional appearance. Accurate measurements prevent costly mistakes and material waste.

- Mark the installation area boundaries with chalk line

- Establish reference points for vertical and horizontal alignment

- Calculate panel layout to minimize cuts and waste

- Mark mounting point locations with precision

- Account for expansion joints and building movement

Framework and Mounting System Installation

Structural Foundation: Install a robust mounting system that will support the weight of the artificial materials and withstand environmental forces.

- Install primary support brackets at specified intervals

- Use appropriate fasteners for the substrate material

- Ensure all brackets are level and properly spaced

- Apply thread-locking compound to prevent loosening

- Test the strength of each mounting point

Panel Installation and Alignment

Precise Placement: Install panels in the correct sequence, ensuring perfect alignment and seamless transitions between sections.

- Begin installation from a corner or reference point

- Check alignment frequently with level and measuring tools

- Secure panels with appropriate fasteners and spacing

- Ensure consistent gaps between panels for natural appearance

- Make precise cuts for outlets, fixtures, and obstacles

Seaming and Finishing

Professional Finishing: Complete the installation with proper seaming techniques and finishing touches that create a seamless, natural appearance.

- Blend seams between panels for invisible transitions

- Adjust foliage density for consistent appearance

- Install edge trim and corner pieces

- Apply any final protective treatments

- Remove all installation debris and clean work area

Quality Control and Final Inspection

Professional Standards: Conduct thorough quality control checks to ensure installation meets professional standards and customer expectations.

- Verify all fasteners are properly tightened

- Check for any loose or damaged foliage

- Ensure consistent appearance across entire installation

- Test stability of all mounted sections

- Document installation with photos and completion certificate

Installation Techniques by Application Type

Artificial Hedge Installation

Hedge installations require attention to alignment, height consistency, and secure mounting to withstand wind loads and seasonal movement.

Critical Hedge Installation Points

- Post Spacing: Install support posts every 6-8 feet for stability

- Ground Clearance: Maintain 2-3 inches above ground level

- Wind Resistance: Use additional bracing in high-wind areas

- Corner Treatment: Install corner brackets for 90-degree turns

- Gate Integration: Plan for gate posts and hardware clearance

Living Wall Installation

Living walls require careful attention to structural mounting, weight distribution, and access for maintenance.

Weight Considerations: Large living walls can weigh 3-5 pounds per square foot. Ensure the mounting surface can support the full load plus wind and seismic forces.

Living Wall Specific Requirements

- Structural Analysis: Verify wall capacity before installation

- Mounting Grid: Install support grid at 16-24 inch centers

- Drainage Considerations: Ensure proper water management

- Electrical Coordination: Plan for any integrated lighting

- Maintenance Access: Design for ongoing care and repairs

Commercial and Hospitality Considerations

Commercial installations require additional considerations for safety, accessibility, and durability.

Commercial Installation Standards

- Building Code Compliance: Meet all local fire and safety codes

- ADA Accessibility: Maintain required clearances and access

- Vandal Resistance: Use tamper-resistant fasteners

- Maintenance Planning: Design for easy cleaning and repairs

- Safety Signage: Install appropriate warning and information signs

Common Installation Issues and Solutions

Problem: Uneven or Wavy Appearance

Solution:

Check mounting bracket alignment and spacing. Use a string line to verify straightness. Adjust bracket positions and ensure consistent spacing between panels. Consider using a laser level for long runs.

Problem: Visible Gaps Between Panels

Solution:

Adjust panel positioning to create natural overlaps. Use additional foliage or filler materials to blend seams. Ensure proper panel size selection for the installation area.

Problem: Loose or Unstable Mounting

Solution:

Verify substrate material and use appropriate fasteners. Consider using toggle bolts for hollow walls or expansion anchors for masonry. Add additional mounting points for heavy installations.

Problem: Difficulty Cutting Panels

Solution:

Use sharp utility knives for backing material and fine-tooth saws for frames. Support panels properly during cutting. Consider using a template for complex cuts around obstacles.

Problem: Wind Movement and Noise

Solution:

Install wind clips or additional fasteners. Consider using solid backing panels in high-wind areas. Add dampening materials between panels and mounting surface.

Post-Installation Care and Maintenance Setup

Proper installation sets the foundation for years of low-maintenance service. Establish maintenance procedures immediately after installation.

Initial Maintenance Schedule

- 30-Day Inspection: Check all fasteners and connections

- 90-Day Review: Assess overall condition and make adjustments

- Annual Inspection: Comprehensive evaluation and preventive maintenance

- Seasonal Preparation: Prepare for weather changes and environmental stresses

Maintenance Documentation

- Provide clients with comprehensive maintenance documentation including:

- Installation warranty and specifications

- Cleaning and care instructions

- Troubleshooting guide for common issues

- Contact information for service and support

- Replacement part ordering information

Professional Installation Guarantee: Proper installation following these guidelines ensures optimal performance and longevity of your artificial landscape materials. Document all installation details for warranty and maintenance purposes.